Cutting

Responding rapidly to the needs of our customers is a top priority. To that end, we maintain a substantial stock of raw materials and use cutting-edge sawing equipment.

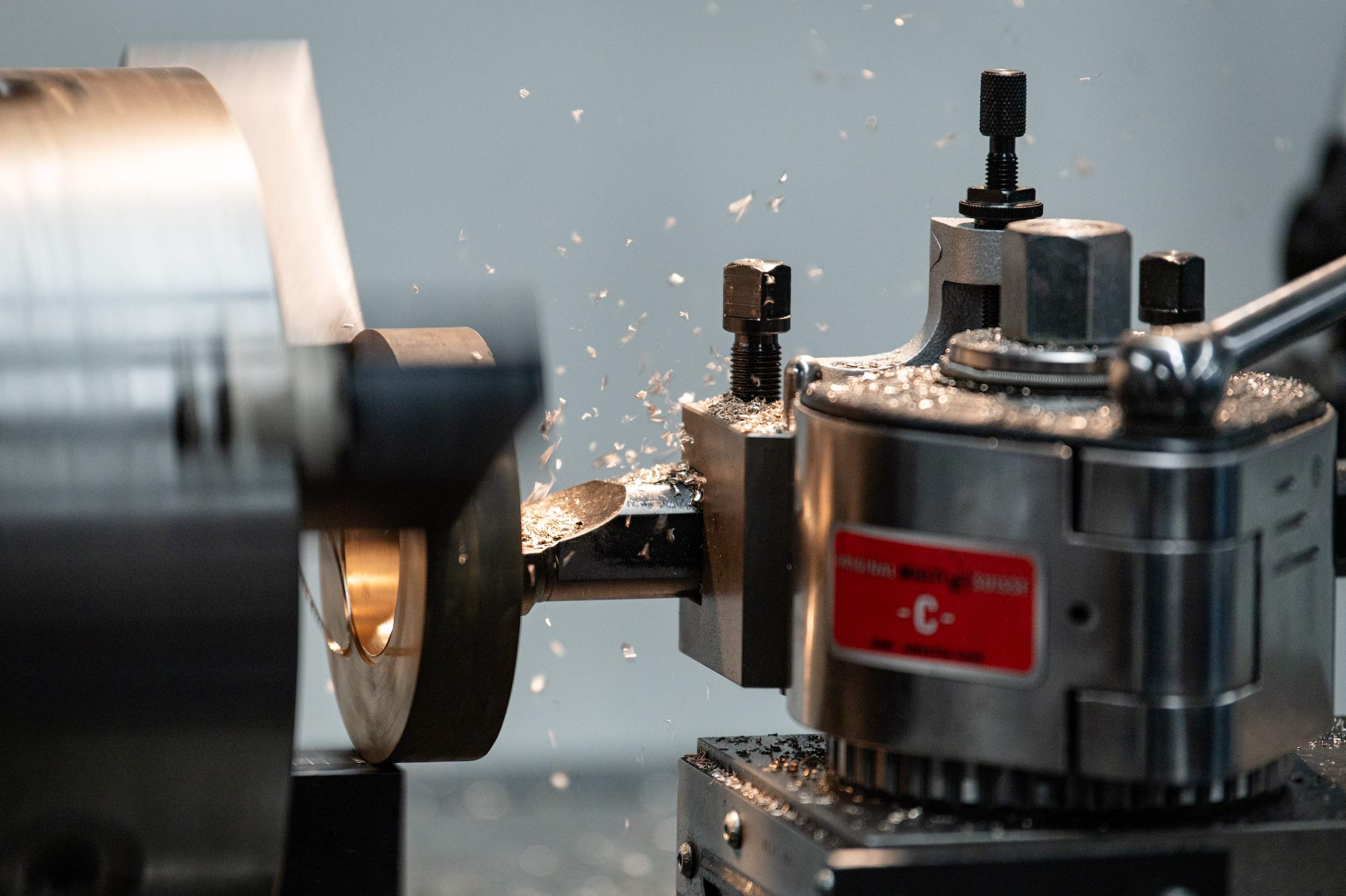

Machining

Our machining hall is equipped with the latest technology: traditional lathes (including one with 6 metres between centres), Teach-in lathes, and milling machines.

This workshop is supported by a substantial stock of raw materials and a wide range of spare parts so as to be able to respond in optimal fashion.

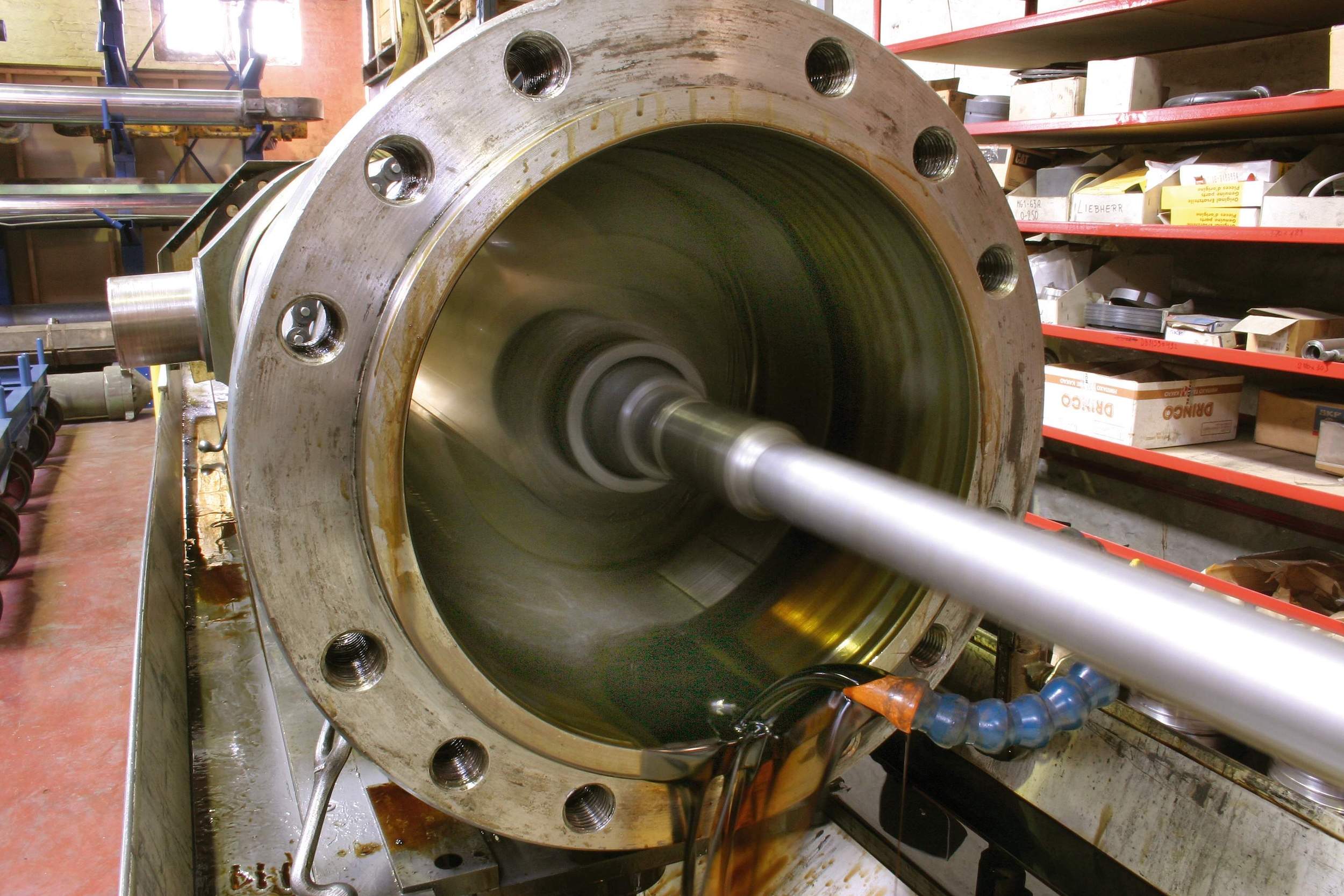

Honing

An automatic honing machine is used to hone tubes from Ø63 to Ø405 mm, up to 3.5 metres in length (or 7 metres with reversal). Each machined or honed part is meticulously inspected by our metrology department to ensure flawless quality.

Hard chrome plating

We use the vertical bath technique to offer hard chrome plating for all types of rods. We can also provide nickel-chrome plating and special coatings such as ceramic or chemical nickel plating, adapted to your specific requirements, upon request.

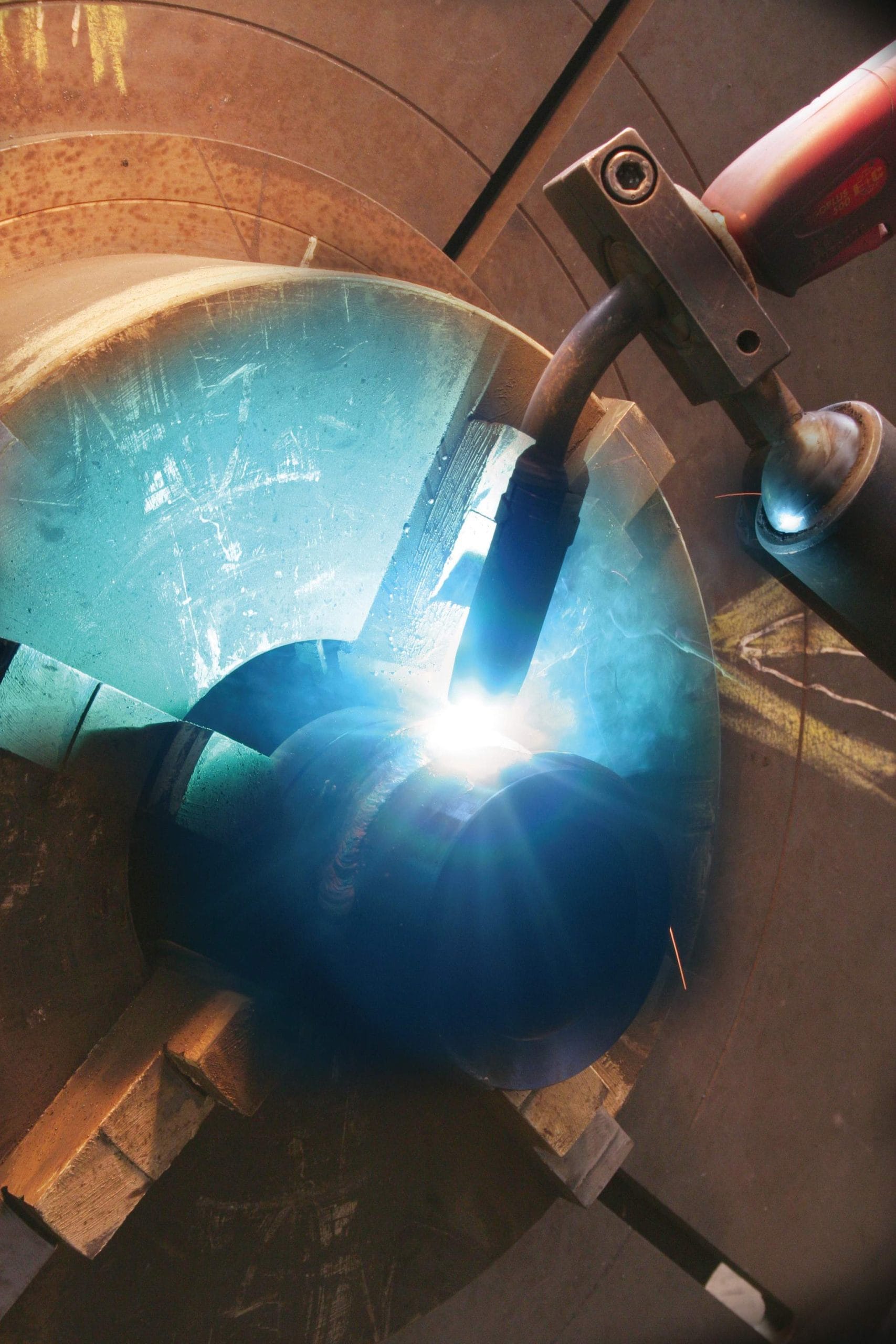

Welding

We primarily use the MIG welding technique, with welds performed on rotators in automatic or semi-automatic mode.

We also master TIG and electrode welding, ensuring versatility and optimal quality.

Assembly

Assembly is carried out under optimal conditions for speed and precision.

This is made possible by our advanced infrastructure (overhead cranes, jibs, forklifts, etc.) and our team of hydraulic cylinder specialists.

Testing

Once assembled, all repaired cylinders are tested on our test bench, a report is provided. Our technical sales team provides a detailed test report, replicating your real operating conditions as closely as possible. This is why we guarantee all repairs carried out in our workshop.

Paint

After passing through our paint booth, where it is given an appropriate coating, each cylinder is delivered looking like new.